If you’ve recycled your precious metals at MGS and watched the refining process, you probably noticed that scrap isn’t the only material going into the furnace. Periodically, we add a bit of flux to the crucible and stir it into the melt. Some clients say it looks like chefs adding a secret ingredient to their stew. Flux is a critical component of the refining process, so that analogy is pretty accurate (although, you definitely wouldn’t want to taste what we’re cooking)! But what is flux exactly and what does it do?

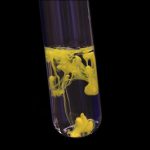

In metal refining, flux is used to help remove impurities and change the fluidity of the melt. Once activated by the furnace’s high temperatures, the flux breaks down and lowers the melting points of all the other materials in the crucible. As the refining process continues, the flux causes the other materials to oxidize and breakdown even further. One of gold’s most noteworthy properties is that it is extremely resistant to oxidation, so it’s unaffected by this reaction and sinks to the bottom. However, the impurities in the melt are not, so they rise to the surface as slag. We’ll add more flux if the slag at the top starts to harden, or when we want the melt to pour more easily.

The composition of flux varies depending on the materials being melted. Some common ingredients in refining flux are anhydrous borax, boric acid, soda ash, silica, fluorspar, potassium carbonate, and manganese dioxide. So in other words, the recipe varies.